Challenge

Outdated systems have the potential to transform assets into liabilities. It is important to know the signs and risks of using outdated systems, and when it is the right time to invest in a modern solution. This was a challenge faced by a company specializing in environmental management services who was operating eleven water well sites across a five-mile area. These sites were being controlled by legacy PLCs and HMIs and relied on slow serial radios for communication, posing several risks such as high maintenance costs, poor HMI responsiveness, and limited scalability due to the outdated equipment. The customer recognized how their outdated system negatively affected their productivity and efficiency which prompted them to seek engineering support. The company engaged Automation Group to design and deploy a modern solution, which included upgrading their PLC, HMI, and radio controls as well as install an additional water well to expand their operations.

Solution

Before installing the new water well, the project team focused on updating the customer’s existing hardware which included the PLCs, HMIs, and radio controls. Automation Group partnered with Applied Technology Group, a company specialized in radio controls, to investigate how to implement a modern Ethernet communications protocol for the customer with minimal disruption to their operations. The research concluded that the best order to implement the upgrades was in two phases. The first phase was to upgrade the Access Point (AP) radio at the customer’s control office, and then upgrade the remote radios that communicate to the AP radio and the main control PLC. With this information, Automation Group began developing the updated system.

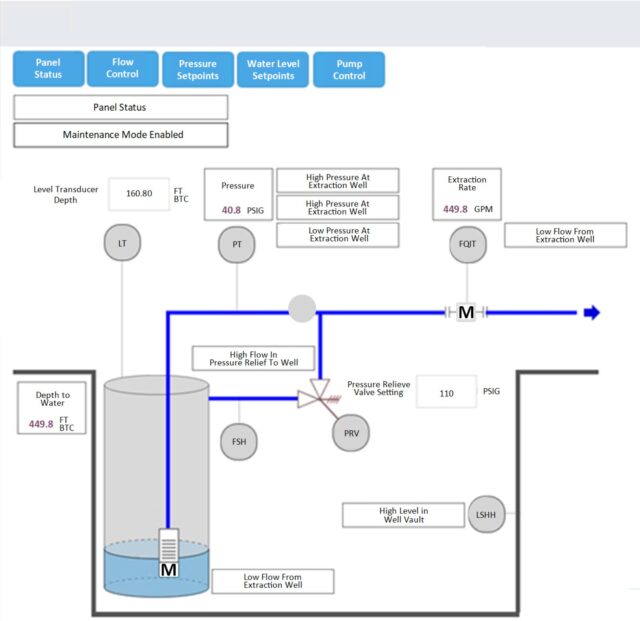

The project team upgraded 13 legacy SLC controllers and Panel Views for newer CompactLogix controllers and Panel View 7 Plus terminals, using Studio5000 and FactoryTalk View Studio to program them. The application also integrated Inductive Automation’s Ignition Perspective SCADA system which provided an operation and management overview of the wells status to the customer’s local and corporate offices.

The project team set up an intermediate infrastructure at the customer’s control office that could run the water well upgrades in parallel with the legacy system. The team installed the new PLCs to run concurrently with the legacy PLCs, and configured messaging between the controllers so the main legacy PLC was unaware of the upgrades.

The team then upgraded the customer’s networking communications from serial radios to Ethernet radios with a more powerful antenna. Lastly, the project team decommissioned the legacy PLC and converted the water wells to run exclusively on the upgraded system.

Throughout this process, Automation Group also resolved challenges with the customer’s remote water wells which faced poor connections from antenna height limitations. The team implemented a store-and-forward capability for the remote radios, which transmitted data to a closer radio station and then forwarded to the main AP radio to improve data connectivity.

After modernizing the existing water wells, Automation Group installed and commissioned the new water well.

Results

The project, including the design and control panel construction for the new water well, was completed in just a few short months. Automation Group successfully supported the modernization of the customer’s outdated system by assigning subject matter experts in network design, radio configuration, PLC/HMI coding and conversions, and the Ignition Perspective module to the project. The implementation of the new system resulted in significant enhancements for the customer in terms of speed and reliability. They now have real-time data available on a per-second basis instead of waiting for minutes, allowing them to depend on it more effectively. Moreover, the customer managed to expand their existing infrastructure by integrating the new water well, effectively meeting their growing demands and overcoming the challenges posed by their previous outdated system.